In the realm of industrial operations, efficiency isn’t just an overused tagline—it’s a critical component that can make or break a company’s bottom line. For industrial engineers and plant managers, the quest for operational efficiency often leads to the heart of their processes: pump solutions. Pumps are the lifeline of many industrial systems, responsible for moving fluids, maintaining pressures, and ensuring smooth operational flow. This blog post aims to explore how cutting-edge pump solutions can transform industrial efficiency, highlighting key technologies, practical tips, and future trends. By the end of this post, you’ll understand why advanced pump technology is indispensable in modern industrial settings and how you can leverage it for maximum efficiency.

Traditional Pump Systems and Their Limitations

The Old Guard of Pump Technology

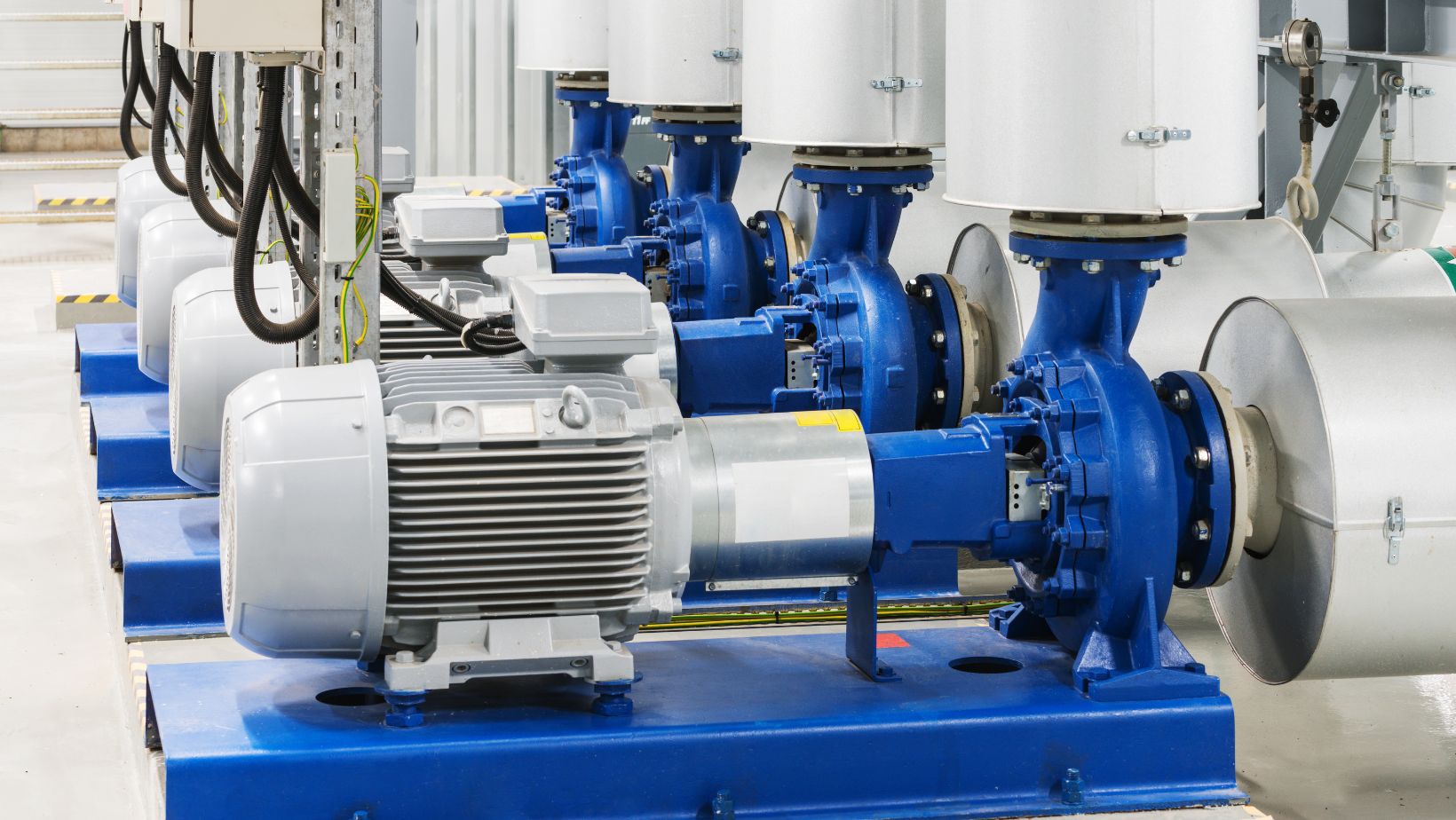

Traditional pump systems have been the workhorses of industrial operations for decades. They include centrifugal pumps, positive displacement pumps, and diaphragm pumps, among others. While these systems have proven their reliability over time, they come with inherent limitations that can hinder overall efficiency.

Energy Consumption and Maintenance Woes

One of the primary drawbacks of traditional pump systems is their energy consumption. These pumps often require significant power to operate, leading to high energy costs. Additionally, maintenance can be a constant headache. Traditional pumps frequently suffer from wear and tear, necessitating regular upkeep that can disrupt operations and add to costs.

Limited Adaptability and Control

Traditional pumps also lack the adaptability and precise control offered by modern technologies. They often operate at fixed speeds and flow rates, making it difficult to adjust to varying operational conditions. This limitation can lead to inefficiencies, especially in processes that require fine-tuning and precise control over fluid dynamics.

The Emergence of Cutting-Edge Pump Technologies

A New Era in Pump Solutions

Cutting-edge pump technologies are transforming industrial efficiency by addressing the limitations of traditional systems. Modern pumps are designed for high energy efficiency, offering significant reductions in power consumption. Additionally, advancements in automation and smart controls enable precise monitoring and adjustment of flow rates, adapting seamlessly to changing operational needs.

This flexibility not only minimizes waste but also optimizes performance across various applications. For industries that require robust solutions, such as dredging, they can read more about dredge and slurry pump solutions, options, and specifications. Understanding these innovations becomes essential, as they promote proper operation and improve efficiency while exemplifying the benefits of modern engineering in fluid management.

Benefits of Smart Pump Systems

Smart pump systems are equipped with sensors and connected to IoT platforms, enabling real-time monitoring and predictive maintenance. This reduces downtime and extends the lifespan of the equipment. AI algorithms can optimize pump operation, adjusting parameters to match real-time demands, thereby conserving energy and reducing operational costs.

Variable Speed Drives and Advanced Materials

Variable speed drives (VSDs) allow pumps to operate at optimal speeds, adapting to changing conditions and reducing energy consumption. Additionally, the use of advanced materials, such as corrosion-resistant alloys and composites, enhances the durability and efficiency of pumps, minimizing maintenance needs and prolonging service life.

Case Studies of Successful Integration

Pharmaceutical Industry

In the pharmaceutical industry, where precision is paramount, the integration of cutting-edge pump solutions has proven revolutionary. Companies have reported improvements in batch consistency and a significant reduction in waste, thanks to the precise control and monitoring capabilities of modern pumps.

Water Treatment Facilities

Water treatment plants have also benefited greatly from advanced pump technologies. By employing smart pumps with real-time monitoring and adaptive controls, these facilities have achieved remarkable energy savings and enhanced operational reliability, ensuring a consistent supply of clean water.

Oil and Gas Sector

The oil and gas industry, known for its demanding operational conditions, has seen substantial gains in efficiency through the adoption of advanced pump solutions. Enhanced durability and reduced maintenance requirements have led to lower operational costs and minimized downtime, critical factors in this high-stakes environment.

Practical Tips for Selection and Implementation

Assess Your Needs

Before selecting a pump solution, conduct a thorough assessment of your operational needs. Identify the specific requirements of your processes, including flow rates, pressures, and fluid types. This will help you choose a pump that matches your unique demands.

Look for Scalability

Choose pump systems that offer scalability.

Your operations may grow or change over time, and having a pump solution that can adapt to varying conditions will save you from future headaches and additional investments.

Prioritize Efficiency and Control

Opt for pumps that provide high efficiency and precise control. Features such as variable speed drives and smart controllers can significantly enhance the performance of the pump, leading to better overall efficiency and reduced energy consumption.

Future Trends in Pump Technology

Increased Adoption of IoT and AI

The future of pump technology lies in the increased adoption of IoT and AI. These technologies will continue to evolve, offering even more sophisticated monitoring, predictive maintenance, and autonomous control capabilities, further driving efficiency.

Sustainable and Eco-Friendly Solutions

The push for sustainability will drive the development of eco-friendly pump solutions. Expect to see more pumps designed with energy-efficient components and materials that minimize environmental impact, aligning with global sustainability goals.

Integration with Comprehensive Digital Ecosystems

Future pump systems will likely be part of larger, integrated digital ecosystems. These ecosystems will encompass various aspects of industrial operations, from supply chain management to data analytics, providing a holistic approach to improving efficiency and productivity.

In the fast-paced world of industrial operations, staying ahead of the curve is essential for maintaining competitiveness. Cutting-edge pump solutions offer a powerful means to enhance efficiency, reduce costs, and improve overall operational performance. By understanding the benefits and capabilities of these advanced systems, industrial engineers and plant managers can make informed decisions that will drive their organizations toward greater success.