Introduction: The End of Guesswork

The global supply chain—a labyrinth of ships, trucks, warehouses, and digital transactions—is the circulatory system of the modern economy. For decades, this system operated on linear planning, historical averages, and educated guesswork. The fragility of this approach was brutally exposed by recent global disruptions, from pandemics to geopolitical conflicts, which transformed predictable delays into systemic failures. Today, the world of logistics is undergoing a radical, AI-driven transformation.

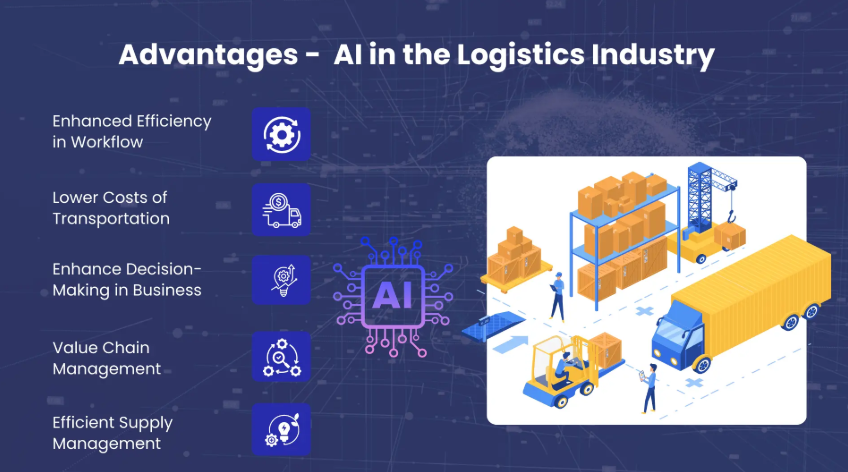

This shift involves evolving the supply chain from a reactive network into a proactive, self-optimizing ecosystem. The AI revolution in this sector is not just about automating warehouse movements; it is about leveraging Predictive Analytics, Causal Inference, and Agentic AI to foresee disruptions, understand their complex ripple effects, and execute autonomous corrective action before human managers even log in. This level of integrated complexity and autonomous decision-making requires highly advanced, unified AI platforms capable of managing vast data flows across disparate systems, like those pioneering solutions found via the official website.

The Shift from Correlation to Causal Inference

Early applications of AI in logistics focused primarily on forecasting. Companies used machine learning (ML) models to analyze historical sales data, weather patterns, and seasonality to predict demand for the next quarter. This solved the problem of what would likely happen, but not why the system might fail.

The current generation of AI moves beyond simple correlation to embrace causal inference. This is the ability of an AI system to not only identify that two events are related (e.g., a port closure and delayed factory production) but to prove that one event caused the other, and to quantify the precise magnitude of that impact.

By establishing a causal baseline—a digital twin of the entire supply chain with all dependencies mapped—the AI can run real-time counterfactual simulations. When a container ship is delayed by five days off a critical port, the system doesn’t just flag the delay; it calculates:

- The exact percentage increase in risk of a specific assembly line running out of components.

- The optimal rerouting path for only the highest-priority containers to mitigate the financial damage.

- The downstream ripple effect on inventory levels three weeks later in four different regional distribution centers.

This sophisticated level of understanding transforms crisis management from an emergency response into a calculated adjustment. As highlighted by Liu et al., 2024, digital twins in logistics operations have the potential to innovate or enhance key services such as monitoring, evaluation, prediction, optimization, control, and system integration.

Furthermore, the integration of causal machine learning into supply chain risk prediction models enables the development of intervention strategies that go beyond mere correlation-based forecasting. Wyrembek (2025) discusses how causal machine learning can be utilized to develop supply chain risk intervention models, providing a more robust framework for decision-making.

These advancements underscore the importance of moving from correlation-based approaches to causal inference in AI applications within logistics, leading to more informed and effective decision-making processes.

From Automation to Agentic Logistics

The ultimate goal of the AI-driven supply chain is the transition from simple automation to full autonomy. Automation is task-focused (e.g., a robotic arm picking a box). Autonomy is goal-focused, managed by an AI Agent.

An Agentic Logistics System is given a high-level strategic goal—for example, “Maintain a 98% on-time delivery rate while minimizing transportation costs by 5%.” The agent then independently executes a recursive loop to achieve that goal:

- Planning: It breaks the goal into sequential sub-tasks (e.g., re-optimize all daily truck routes; renegotiate short-term carrier contracts; adjust warehouse staging protocols).

- Execution: It accesses and operates disparate systems (TMS, WMS, ERP).

- Reflection: It monitors the results (e.g., “Transportation costs dropped by 4%, but the on-time rate fell to 97.5%”). It then autonomously revises the plan—perhaps slightly increasing budget for next-day air freight—and re-executes.

This Plan-Execute-Reflect cycle allows the supply chain to become a self-healing entity. It reacts to real-time variables like traffic, weather, component failures, and labor shortages with minimal human intervention, ensuring the continuous flow of goods according to strategic objectives.

Four Critical Use Cases of Agentic AI

The deployment of autonomous agents is focusing on the most complex and costly bottlenecks in the supply chain:

1. Dynamic Inventory Optimization

Traditional inventory relies on safety stock and static reorder points. AI agents use real-time demand signals, social media trends, and hyper-local events to perform micro-forecasting. They don’t just order more product; they predict which specific distribution center will need which specific SKU at what precise hour, virtually eliminating capital tied up in unnecessary inventory while preventing stockouts.

2. Autonomous Routing and Dispatch

In LTL (Less Than Truckload) and last-mile delivery, route optimization is a constant battle against traffic and unexpected events. An AI agent manages the entire fleet in real-time. If a truck breaks down, the agent doesn’t just notify a dispatcher; it instantly reassigns the stranded cargo to the two closest available drivers, updates customer ETAs via SMS, and generates the necessary maintenance report for the broken vehicle—all simultaneously.

3. Predictive Maintenance of Assets

From port cranes to conveyor belts, equipment downtime is catastrophic. AI analyzes vibration, temperature, acoustic, and utilization data from thousands of sensors. It can predict, with days or even weeks of warning, when a specific component is likely to fail. This allows the system to schedule maintenance proactively during low-volume periods, entirely preventing costly, unscheduled shutdowns.

4. Global Risk Sensing

AI agents continuously monitor news, regulatory changes, climate models, and geopolitical risk indicators across the globe. If a new trade tariff is announced in a major market, the agent immediately simulates the cost increase across all affected products and presents a dashboard detailing new tariff rates, the optimized sourcing alternatives, and the projected financial impact, allowing executives to pivot strategy within hours rather than weeks.

The New Human Role: Director of Autonomy

The transformation of the supply chain is not about replacing the logistics professional, but elevating their role. The logistics manager of the future will not be burdened with routine tracking, manual data entry, or crisis firefighting. Their new title is Director of Autonomy.

The most valuable skills shift from execution to strategy, oversight, and ethical governance. The human task becomes:

- Setting the High-Level Goal: Defining the strategic parameters and KPIs the AI must adhere to (e.g., prioritizing speed over cost, or sustainability over profit margin).

- Curating the AI’s Outputs: Providing the final, critical judgment on complex, nuanced outputs where data might conflict with cultural or human factors.

- Managing the Exceptions: Stepping in only when the AI reports a situation that falls outside its programmed parameters, thus focusing human genius solely on truly novel problems.

By delegating the vast complexity of day-to-day operations to AI agents, human expertise is amplified, ensuring that the supply chain operates with unprecedented efficiency while remaining guided by strategic intent.

Conclusion

The AI-driven revolution in the supply chain is fundamentally changing the calculus of business risk and operational speed. By moving from reactive, correlation-based planning to proactive, agentic autonomy, companies are building supply chains that are resilient, intelligent, and highly adaptable. This transformation is only possible through integrated computational platforms that can manage and orchestrate these complex, goal-oriented AI systems across the entire logistics spectrum. The future of commerce is already here, running silently and autonomously, ensuring the world’s goods keep moving, no matter what disruptions lie ahead.