In a competitive retail landscape where customer satisfaction and operational efficiency can make or break a business, inventory management is a core challenge. Replenishment software has become essential for retailers looking to optimize stock levels and respond to consumer demand without delays. According to Future Market Insights, the inventory management software market is projected to grow from $2.19 billion in 2024 to $7.52 billion by 2034, reflecting a CAGR of 13.1%. This technology helps businesses stay lean, agile, and profitable by using real-time data to automate and streamline restocking. Let’s explore why replenishment software is not just a tool, but a strategic advantage for modern retailers.

Why Retailers Rely on Replenishment Software

Retail operations depend on having the right products, in the right quantity, at the right time. Replenishment software helps ensure that balance is achieved consistently and efficiently. For example, inventory replenishment software like LEAFIO.AI automates the entire replenishment process, enabling quick identification of bottlenecks and enhancing supply chain efficiency. It simplifies retail chain scaling by centralizing purchase order management, reducing operational costs, and promoting data unification for better inventory insights. Additionally, the software allows managers to focus on strategic tasks, minimizes the risk of missed orders, and improves overall financial performance, potentially increasing sales by up to 7%. Let’s dive deeper into why technology is indispensable in retail today:

1. Minimizing Stockouts and Overstocks

Stockouts frustrate customers and lead to lost sales, while overstocks tie up capital and increase storage costs. Replenishment software uses predictive analytics to maintain optimal inventory levels. It accounts for sales trends, seasonality, and supplier lead times, making it much more accurate than manual forecasting. As a result, retailers reduce both types of inventory errors and improve cash flow.

More importantly, by preventing these common issues, businesses can enhance customer trust and satisfaction. When shoppers consistently find what they need, they are more likely to return. On the other hand, poor inventory management can drive loyal customers to competitors. The value of replenishment software lies in its ability to fine-tune supply and demand balance at all times, ensuring the shelves are never too empty or too full.

2. Automating Reordering Processes

Manual reordering is slow, error-prone, and inconsistent. Replenishment software automates these tasks using rules-based systems and machine learning. Orders are triggered when stock levels fall below predefined thresholds, with timing and quantity calculated to align with demand patterns. This frees staff to focus on customer service and strategic planning instead of administrative tasks.

The automation ensures consistency and reliability that manual processes struggle to deliver. Retailers can set specific parameters for different product categories, allowing for a customized approach to restocking. This reduces human error and also allows businesses to respond more quickly to shifts in consumer demand. During high-demand seasons, the software can dynamically adjust to ensure the right products are replenished on time, avoiding the chaos of last-minute stock runs.

3. Enhancing Supply Chain Visibility

A lack of real-time insights into inventory across multiple locations weakens supply chain decisions. Replenishment software provides centralized, up-to-date views of stock, helping managers identify bottlenecks, monitor vendor performance, and shift products as needed. Better visibility leads to faster reactions and fewer disruptions, keeping shelves stocked and customers satisfied.

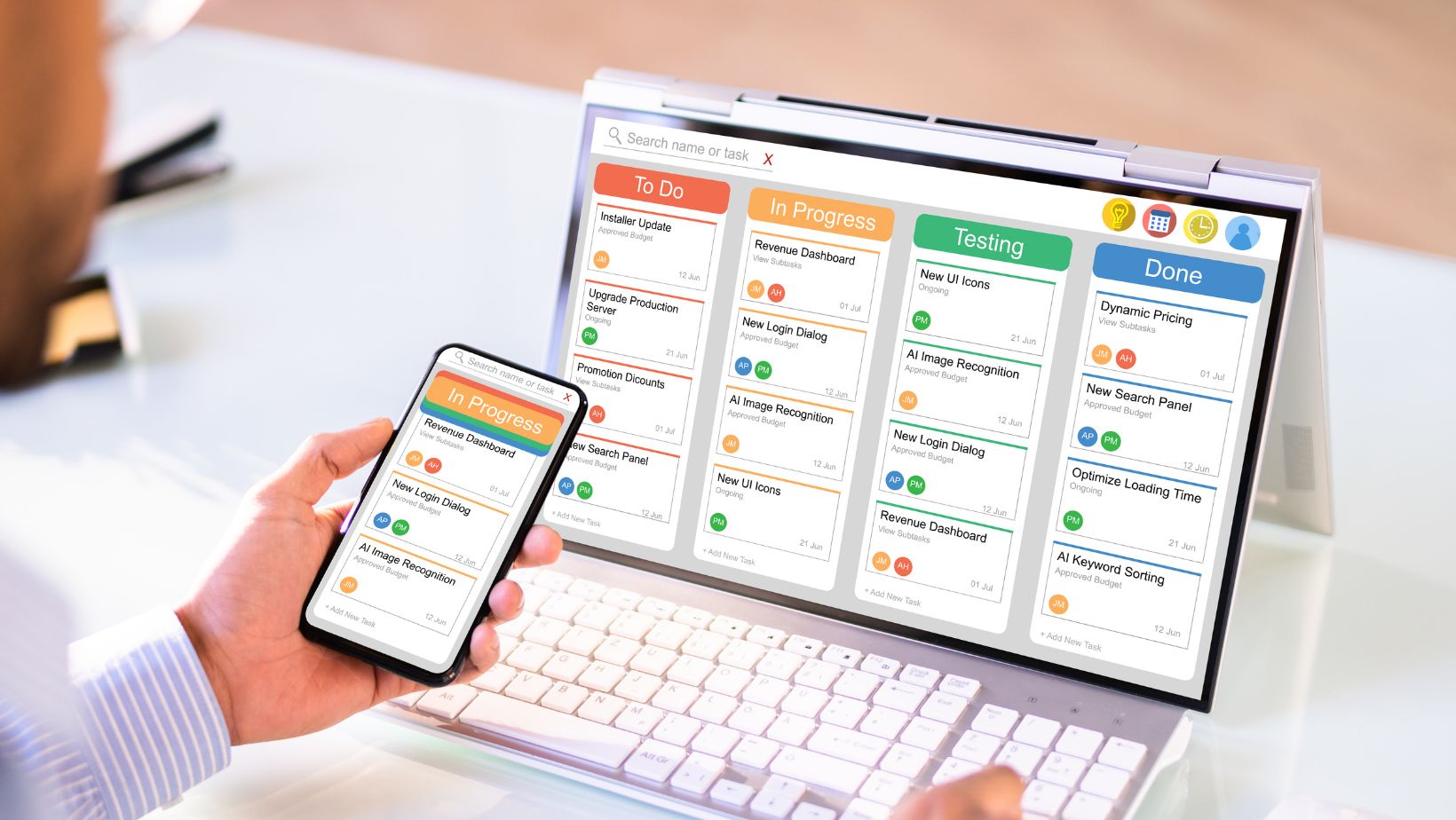

This visibility is especially important for businesses with multiple sales channels—physical stores, e-commerce platforms, and third-party marketplaces. Replenishment software integrates data from all these sources to provide a unified dashboard. Managers can quickly assess where products are moving, where they’re lagging, and make data-driven adjustments. This integrated view reduces the risk of stock misalignment and boosts overall responsiveness.

4. Improving Demand Forecasting Accuracy

Accurate demand forecasting is key to maintaining efficiency. Replenishment software uses AI and data analytics to analyze buying patterns and project future demand with high precision. This is especially valuable for businesses dealing with fast-moving or perishable goods. Better forecasts mean fewer wasted products and more sales opportunities captured.

In the past, forecasting relied heavily on historical sales data and educated guesses. Modern replenishment software goes several steps further by incorporating variables such as weather, holidays, promotions, and even local events. These inputs give retailers a deeper understanding of what drives sales fluctuations. The more accurate the forecast, the more precisely inventory can be managed, leading to higher profitability and lower risk of stock obsolescence.

5. Scaling with Business Growth

As retailers expand to new locations or sales channels, complexity increases. Replenishment software is built to scale, managing larger data sets and coordinating stock across more touchpoints. Its automation and analytics capabilities adapt to business size, helping maintain consistency and control even during rapid growth.

Without a scalable system, growth often leads to operational chaos—disorganized stock rooms, delays in deliveries, and frustrated customers.

Replenishment software handles increasing inventory and transactional volumes without breaking down. Whether adding ten new stores or expanding to international markets, businesses can maintain high performance standards and operational harmony. It also provides leaders with the strategic insights needed to plan future growth with confidence.

6. Reducing Operational Costs

Efficiency isn’t just about speed—it’s also about reducing unnecessary spending. By avoiding overstock, lowering spoilage, and cutting labor costs associated with manual tracking, replenishment software drives down expenses. Over time, this has a noticeable impact on the bottom line and allows for reinvestment into other areas of the business.

Operational cost savings go beyond simple reductions in labor. When inventory turnover improves, storage space is used more effectively. There is also less need for emergency orders, which are often more expensive due to rush shipping or last-minute logistics. Moreover, replenishment software reduces shrinkage and loss by keeping inventory accurate and accounted for. Every saved dollar can be reinvested in marketing, technology upgrades, or employee development—areas that support long-term success.

Conclusion

Retail success today requires fast, accurate, and adaptive inventory management. Replenishment software delivers that by turning complex data into clear, actionable decisions. It reduces errors, boosts efficiency, and strengthens a retailer’s ability to compete in a demanding market. Let’s harness the power of replenishment software to make retail operations smarter, smoother, and more profitable.