Did you know CNC machining technology in China dates back to the ‘50s? Since the arrival of precision CNC machining technology, there has not been a turning back. Today, China produces numerous CNC parts, backed by advanced technology, skilled workforce, and a vast market.

CNC metal machining involves rotating a metal workpiece on a lathe. A single-point cutting tool shapes the rotating workpiece. Precise details fed into the machine’s control panel ensure the production of detailed CNC machining metal parts.

Custom CNC machining parts come in all forms and sizes, from nuts and shafts to gears and crankshafts. Many industries use metal parts including automotive, aerospace, and energy.

This post details the different aspects of CNC metal part manufacturing to help you determine how your business can gain.

Popular CNC Metal Machining Processes

Options for CNC machining service are available through various technologies. The most popular ones are:

CNC Metal Parts Milling

A CNC Milling Machine in Action

Alt text: An image of a milling tool machining a block of metal with coolant spread on the surface

What is precision CNC machining through milling? This is a subtractive manufacturing process characterized by the selective removal of material from a metal workpiece. The table, holding the workpiece firmly, rotates on multiple planes to enable the tool to remove material at different angles.

CNC Turning

In CNC turning, the metallic workpiece rotates while the cutting tool removes material to produce a cylindrical form.

It is an ideal method for manufacturing threads,shafts, and related CNC machining metal parts.

Electrical Discharge Machining (EDM)

This machining technique is unique because it is based on material erosion using electrical discharges. Although relatively slow, the EDM method is prominent in industries that manufacture intricate metal parts. Note that this manufacturing method can only work on electrically conductive materials.

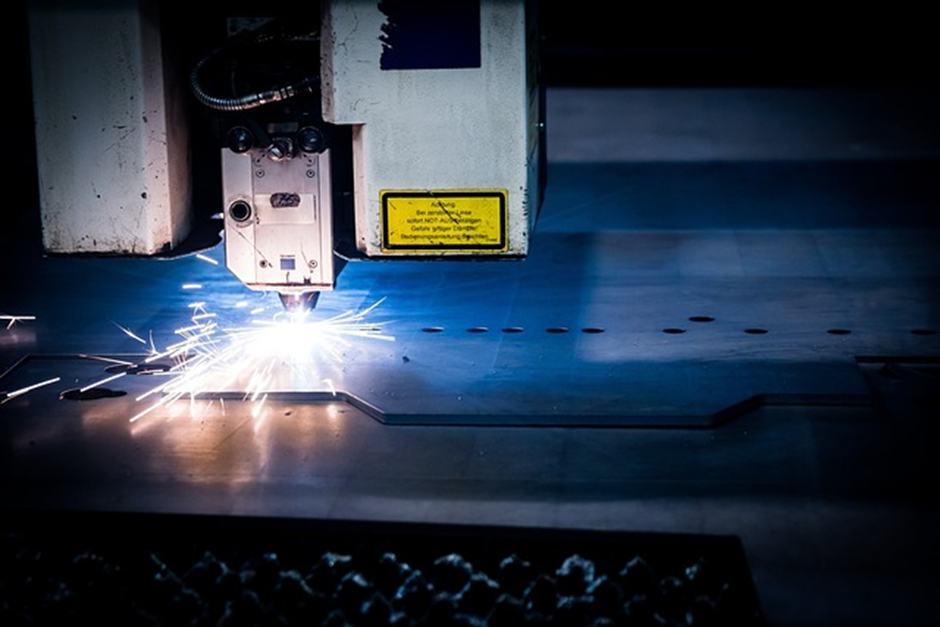

Laser Cutting

A CNC Laser Cutting Machine

Alt text: A close up photo of a CNC laser cutting machine cutting sheet metal and producing bright sparks.

This is another CNC metal part production method that offers great precision. Powerful laser beams strike the metal surface leading to vaporization or melting. Laser cutting applies to a wide range of materials, including plastic.

CNC Drilling

In CNC drilling, what is CNC precision machining? This technique uses specially designed drill bits to create holes in the metal. It is highly versatile and capable of producing holes of varying diameters and depths.

Types of CNC Parts to Consider

At Prolean Tech, metal parts can be categorized based on the material or the machining method. Let’s start with the categorization based on the material.

|

Material |

Properties |

|

Copper |

Ideal for applications requiring high thermal and electrical conductivity |

|

Brass |

Contains copper and zinc. It is suitable for plumbing and decorative items. |

|

Aluminum |

A notable property is high strength-to-weight ratio and machining ease. |

|

Steel |

The material is strong, versatile, and durable. |

|

Titanium |

It is also strong, adding to corrosion resistance and low weight. |

Where Can You Use Metal Parts?

Custom CNC machining parts have various applications in industries. If you work with a manufacturer who delivers quality products, there are many areas where you can confidently use CNC-machined metal parts.

Automotive industry

The use of CNC machining metal parts in this industry is limitless. From tiny pieces to sizable machined metal parts, the automotive industry relies a lot on these parts.

A notable area of application of precision CNC machining is the engine. A big piece of metal can be systematically CNC machined to produce an engine block. The cylinder head and numerous other parts of the engine are CNC parts.

Other parts of a car made from these parts are:

- Exhaust system

- Brakes

- Suspension system

- Interiors

Aerospace industry

CNC machining in the aerospace industry helps make industry-compliant parts. The manufacturing method suits the production of lightweight metals, achieving the strict tolerances needed in the industry.

Some specific technologies that manufacturers in the industry use are CNC milling, CNC turning, and CNC drilling. Notable aircraft CNC machining metal parts are wing skins, bushings, fuel tanks, and hinges.

Industrial machinery

Durable and precise custom CNC machining parts are relevant to industrial machinery. CNC machining offers these capabilities for quality metal parts for industrial machinery applications. Turning, milling, and other machining techniques are reliable for the production of critical parts such as shafts and gears.

Interconnected Metal Gears

Alt text: An image of three blackish greyish mating gears of different sizes

Medical Industry

CNC parts are also part of your processes if you are in the medical industry. Prosthetics, surgical devices, and medical implants are only some areas where you expect to find or use these parts. The metals you would be dealing with for such parts include titanium and aluminum.

CNC machining such parts can be challenging because some materials are barely machinable. Fortunately, expert machinists and advanced CNC machinery handle such challenging tasks.

How to choose a CNC machining parts supplier

It is understandable if you are stuck wondering “What is CNC precision machining?” and selecting a CNC parts partner. Dealing with a lengthy list of requirements for metal parts and an endless array of CNC metal manufacturers can be daunting. Following some criteria when choosing the CNC metal parts manufacturer can make the job easier.

Do they have satisfactory manufacturing capacity?

A worthy metal parts manufacturer should have the necessary CNC equipment, workforce, and tools to deliver the items. It is always a good idea to visit the metal part manufacturing facility before entering into a contract. If that is impossible, at least look at a sample of the part.

What is the cost of the CNC metal parts?

Cost is a reliable criterion when comparing different part suppliers. Make sure the potential company’s charges are within acceptable budget limits.

How good is the quality control system?

A successful CNC machining parts supplier has a robust quality control system. This system guarantees the delivery of quality metal parts and helps safeguard the company’s reputation. You may want to inquire about the manufacturer’s quality control system.

In conclusion

This article has provided important insights into the world of CNC metal parts. Identifying the various types of CNC metal parts, applications, and handy tips can ensure your project’s success. Hopefully, the information shared will be helpful in your next project.

What is your experience with CNC metal parts? Would you like help selecting the best metal parts to make your projects more useful and cost-effective?

Please share your views in the comments section and say if you would be interested in the input of a reputable cnc machining parts supplier.