When a gadget connects to a dock connector, embedded circuits instantly initiate signal detection, power negotiation, and device authentication. This complex process enables safe charging, secure data transfer, and accessory integration through standardised protocols. The hardware automatically negotiates optimal charging rates whilst verifying genuine accessories to prevent counterfeit devices from operating. These precision-engineered connections ensure reliable performance across consumer electronics, medical devices, and industrial applications.

Understanding Dock Connectors

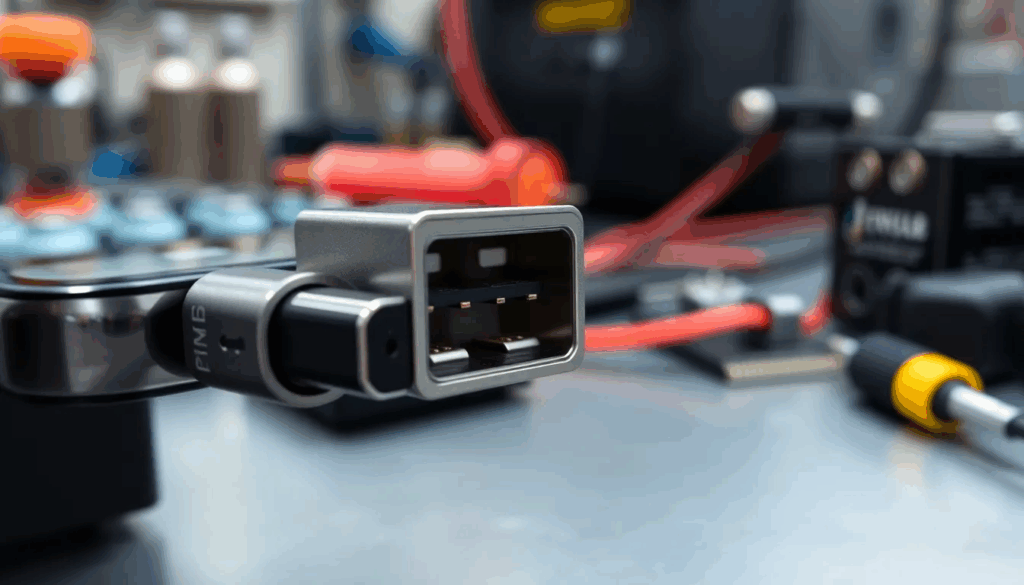

Dock connectors create unified electrical pathways between handheld devices and external systems. They include spring-loaded pogo pins, magnetic connectors, USB-C, and proprietary multi-pin interfaces. Designers select each type based on application-specific criteria like insertion cycles, signal integrity, waterproofing, and space constraints. Pogo pin connectors deliver high cycle life, stable performance, and targeted contact pressure through spring-loaded mechanisms. Engineers use them in smartphones, tablets, medical diagnostic tools, and aerospace data modules for their consistent connection over thousands of uses. Promax manufactures pogo pin assemblies with center spacing options as fine as 0.4 mm, custom spring force, and gold-plated contacts to reduce resistance and oxidation. Magnetic connectors add user safety by quickly disconnecting under force and enable guided alignment for charging docks or wearable electronics. Promax integrates rare-earth magnets and ultra-fine pogo pins to meet requirements in consumer and industrial projects. Custom tooling allows rapid iteration for medical, automotive, and portable computing clients requiring precise mechanical and electrical reliability. Signal and power transmission capacity, durability, ease of use, and miniaturization all factor into connector specification. Electronics engineers and procurement teams source from Promax to meet strict international quality controls, ISO 9001 certification, and tailored production runs for both high- and low-volume needs.The Initial Connection: What Happens First?

Physical connection instantly triggers communication between a gadget and dock connector. Contact points link internal electronics, allowing signals and power to move between both sides.Signal Detection and Power Negotiation

Electronic interfaces initiate signal detection and power negotiation when connectors like pogo pins or USB-C create contact. Embedded circuits identify the type of device using the connection path’s resistance and voltage response. Microcontrollers exchange configuration data at this point to match charging rates, data protocols, or audio-video outputs. For example, a smartphone might negotiate a 5 V, 2 A charging profile using a USB-C dock, but a medical device with a Promax pogo pin connector could require custom voltage thresholds defined during initial handshake. Strict adherence to IEC and UL standards in Promax’s connectors supports safe power negotiation across consumer, industrial, and medical use cases.Device Authentication

Device authentication starts immediately after completing the physical handshake. Communication protocols like USB Power Delivery or proprietary authentication ICs verify accessory identity to prevent counterfeit or unsafe devices from initiating further operations. Security chips or unique resistor values in magnetic and pogo pin connectors encode identity and usage rights, enabling the gadget to accept, restrict, or reject specific accessories. Promax’s spring-loaded and magnetic connector solutions ensure traceable serials or cryptographic signatures to comply with manufacturer security guidelines and regional regulatory requirements in electronics, medical, and aerospace sectors. This authentication step protects both the gadget and user by permitting only validated connections.Data Transfer Mechanisms

Data transfer mechanisms activate instantly when a gadget connects to a dock connector. Precision in connector design and protocol choice enables seamless communication and minimizes latency.Syncing Files and Managing Data

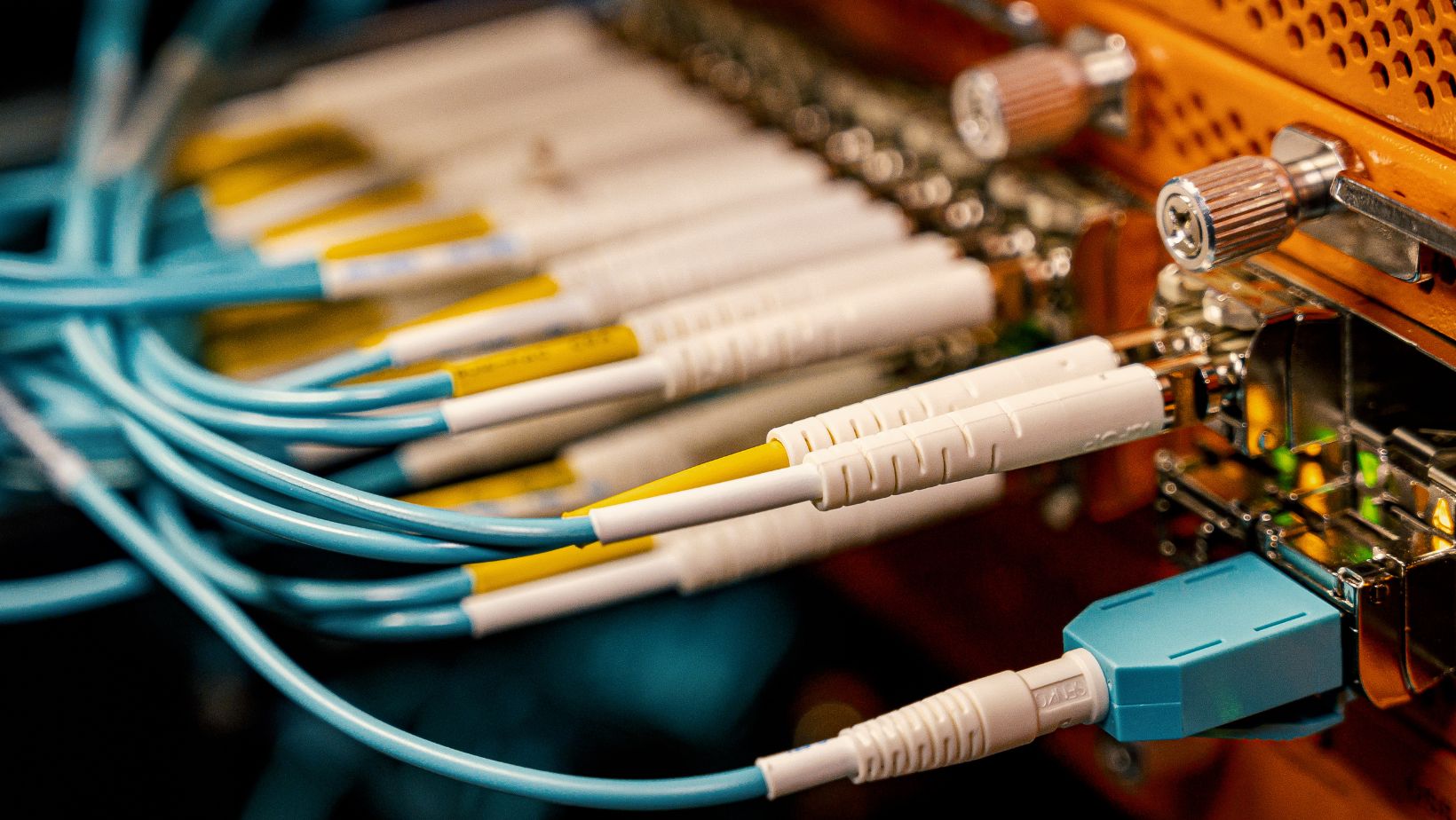

Data syncing begins when the controller inside the device detects an established connection through the pogo pin, USB-C, or magnetic interface. Embedded chips negotiate data rates—480 Mbps for USB 2.0 or 5 Gbps for USB 3.0, for example—based on connector and cable capabilities. Pogo pin connectors, such as those manufactured by Promax, support stable high-speed signals and are used in medical diagnostics and wearable devices for repetitive, secure data transfer. Data packets sync contacts, media, and firmware updates across host and accessory, with onboard encryption ensuring file integrity and privacy.Role of Protocols and Standards

Protocols and standards define how data moves across a dock connector, ensuring cross-compatibility and safety. USB implements standardized signaling, error correction, and power management. Proprietary systems—such as Apple’s Lightning—use custom encryption algorithms and pin mapping. Promax follows IEC, RoHS, and UL standards in pogo pin and magnetic connector manufacturing, enabling export to regulated markets. Compliance testing checks insulation resistance, dielectric strength, and signal crosstalk for each production batch. Protocol adherence guarantees that devices authenticate accessories and maintain consistent communication during operation.Power Delivery and Charging Process

Connecting a gadget to a dock connector initiates the power delivery cycle, where built-in circuits manage energy flow and protect sensitive hardware. High-grade manufacturers like Promax design pogo pin, spring-loaded, and magnetic connectors to maintain stable power transmission and regulatory compliance during charging.Power Handshaking and Regulation

Power handshaking occurs in milliseconds after insertion. Embedded controller ICs detect the connection and exchange specific voltage and current requests. For example, gadgets use USB-C or Promax pogo pin connectors to negotiate supply levels such as 5 V at 3 A, optimizing charge rates for tablets, medical analyzers, or industrial wearables. Regulators inside the device then balance the incoming power, filtering spikes or surges with LDOs or switching circuits. Connector assemblies with gold-plated contacts, like those from Promax, reduce resistance and prevent arcing, which ensures efficient charging cycles over thousands of mating events. Manufacturers certify these assemblies to standards such as IEC 60950 and UL 62368 for global deployment.Battery Health and Safety Features

Battery health and safety features activate during every dock connection. Protection ICs monitor temperature, voltage, and charge cycles, halting power if values move outside preset ranges. For lithium-battery gadgets in aerospace, medical, or smart home devices, Promax spring-loaded contacts enable secure, low-resistance connections that support smart charging logic. Integrated thermistors and eFuse components within docking modules detect abnormal heat or current flow, shutting down charging if risks arise. Conformal-coated pogo pin connectors further protect contacts from corrosion in humid or challenging environments, extending product lifespan for enterprise and consumer markets. Promax subjects all pogo pin connectors to accelerated aging and salt spray tests to meet RoHS and ISO 13485 medical safety standards.Peripheral Integration and Functionality Expansion

Peripheral integration expands gadget capabilities through the dock connector, transforming a device from standalone hardware to a multifunctional system. Functionality increases instantly, connecting power, signals, and control pathways for multiple accessory types.Audio, Video, and Peripheral Support

Peripheral support through dock connectors enables audio transmission to headphones, speakers, and sound docks using dedicated pins for signal clarity. Video output channels transfer high-definition visuals to monitors and projectors, with signal protocols like HDMI or DisplayPort managed by embedded controllers. Data lines within the connector also allow simultaneous communication with keyboards, storage drives, and input peripherals for workstations and medical devices. Promax designs pogo pin and spring-loaded connectors to support multi-channel data and power without interference, providing robust connections for application-specific demands across consumer and medical fields.Dock Connector and Accessory Compatibility

Connector and accessory compatibility depend on embedded identification chips, physical pin mapping, and standardized signaling enforced at the hardware level. Authentic accessories integrate seamlessly when the connector’s detection protocol validates interface logic, enabling features such as fast charging, secure communication, or accessory power delivery regulated through USB Power Delivery, Apple’s MFi protocols, or other custom standards. Promax engineers pogo pins, magnetic connectors, and spring-loaded contacts for direct-fit with global accessory ecosystems, ensuring high cycle durability and regulatory compliance through IEC and RoHS certification. Manufacturers achieve accessory ecosystem stability with Promax’s precision connector solutions, reducing signal degradation and minimizing wear in demanding environments.Common Issues and Troubleshooting

Connection issues and operational errors sometimes occur when connecting gadgets to dock connectors. Fast identification and targeted troubleshooting help maintain stable device functionality.Connection Failures and Error Handling

Contact contamination and connector misalignment represent leading causes of connection failure. Dust, oils, and oxidation on pogo pins or magnetic surfaces interrupt signal continuity, generating device recognition errors or intermittent charging. Misaligned connectors prevent proper mating, resulting in failed connections or accessory detection. Error messages, such as “accessory not supported” or charging icons that flash and disappear, often appear when internal circuits identify unusual resistance or irregular voltage. Stable spring force and precision pin geometry, as seen in Promax pogo pin connectors, reduce cross-connection risks. Engineers restore operation by cleaning connector surfaces, inspecting contact wear, and verifying cable integrity. Replacement of damaged connectors or prompt recalibration of accessory authentication resolves persistent errors in most device-resilient docking designs.Safety Considerations

Short circuit protection and overcurrent prevention improve safety when connecting gadgets. Integrated protection ICs instantly disable power from the dock connector if current surges or foreign material causes a short—common in densely populated connector assemblies. Pogo pin designs from Promax incorporate gold plating and insulated barrels to minimize arcing and oxidation, which protects high-precision medical and wearable gadgets. Designs with magnetic connectors break connection without physical force, which prevents damage if accidental yanking occurs. Heat management, such as the use of thermally conductive plastics and vented housing, maintains safe operating temperatures during high-power transfer. Promax products meet RoHS and UL safety standards, supporting reliable performance in regulated environments like medical and aerospace equipment.

Designs with magnetic connectors break connection without physical force, which prevents damage if accidental yanking occurs. Heat management, such as the use of thermally conductive plastics and vented housing, maintains safe operating temperatures during high-power transfer. Promax products meet RoHS and UL safety standards, supporting reliable performance in regulated environments like medical and aerospace equipment.

Conclusion

Plugging in a dock connector sets off a sophisticated sequence of actions that most users never notice. Behind the scenes devices and connectors work together to ensure safe charging secure data transfer and reliable accessory integration. Understanding these processes not only deepens appreciation for everyday gadgets but also empowers users to make informed choices and maintain their devices effectively. As technology evolves the role of precision-engineered connectors will only become more critical in delivering seamless performance and safety across industries.Frequently Asked Questions

What happens when a gadget is connected to a dock connector?

When a gadget connects to a dock connector, it triggers a sequence where hardware and software work together. This allows the device to sync data, charge its battery, and communicate with attached accessories, all managed by embedded circuits ensuring efficiency and safety.What types of dock connectors are commonly used?

Common types include spring-loaded pogo pins, magnetic connectors, USB-C, and proprietary multi-pin interfaces. Each type is selected based on the device’s requirements for durability, signal integrity, size, and safety features.How do dock connectors negotiate power and data?

Upon connection, embedded controller chips communicate to identify device type, negotiate optimal charging rates, and establish data transfer protocols. This ensures safe charging and efficient data syncing, tailored to each device’s capabilities and needs.Why is device authentication important for dock connectors?

Device authentication helps verify that only genuine or approved accessories can connect. Security measures like unique resistor values and cryptographic signatures in connectors prevent counterfeit devices from operating, enhancing user safety and system reliability.How do dock connectors ensure fast and stable data transfer?

Precision-engineered connectors and standardized signal protocols minimize latency and errors. Devices automatically negotiate the best possible data rates and use error correction to ensure smooth, reliable transfers, even for sensitive applications like medical devices.What safety features are included in dock connectors for charging?

Protection ICs in connectors monitor voltage, current, and temperature during charging. These features prevent overcharging, overheating, and short circuits, helping maintain the safety and longevity of the device’s battery.How do dock connectors support accessories and peripherals?

Dock connectors use dedicated pins and communication protocols to integrate audio, video, and other peripherals seamlessly. Compatibility is managed by embedded chips and standardized signals, allowing for secure connections and advanced features.What causes common issues with dock connectors?

Most issues stem from dirty contacts or misaligned connectors, which can disrupt communication and power delivery. Keeping connectors clean and properly aligned helps maintain stable operation and prevents error messages or connection failures.How do manufacturers like Promax ensure dock connector quality?

Manufacturers like Promax use rigorous testing for insulation, signal strength, and durability. Their connectors meet strict international standards, ensuring reliable performance, safety, and compliance across consumer, medical, and aerospace applications.Are dock connectors safe for use in medical and aerospace equipment?

Yes, quality connectors comply with global standards such as IEC, UL, and RoHS. They undergo thorough testing for reliability and safety, making them suitable for demanding environments like medical and aerospace applications.