Sheet metal is a versatile material used in many industries, from construction to automotive to electronics. It is thin and flat, making it easy to shape and form into various products. In this article, we will explore the different types of sheet metal and the fabrication techniques used to turn these sheets into useful items.

What Is Sheet Metal?

Sheet metal is a flat piece of metal that has been processed to be thin, usually less than a few millimeters thick. It is made from a variety of metals, such as steel, aluminum, copper, and brass. The flexibility of sheet metal makes it ideal for cutting, bending, and forming into various shapes.

Types of Sheet Metal

There are several types of sheet metal, each with unique properties. Let’s look at the most common ones:

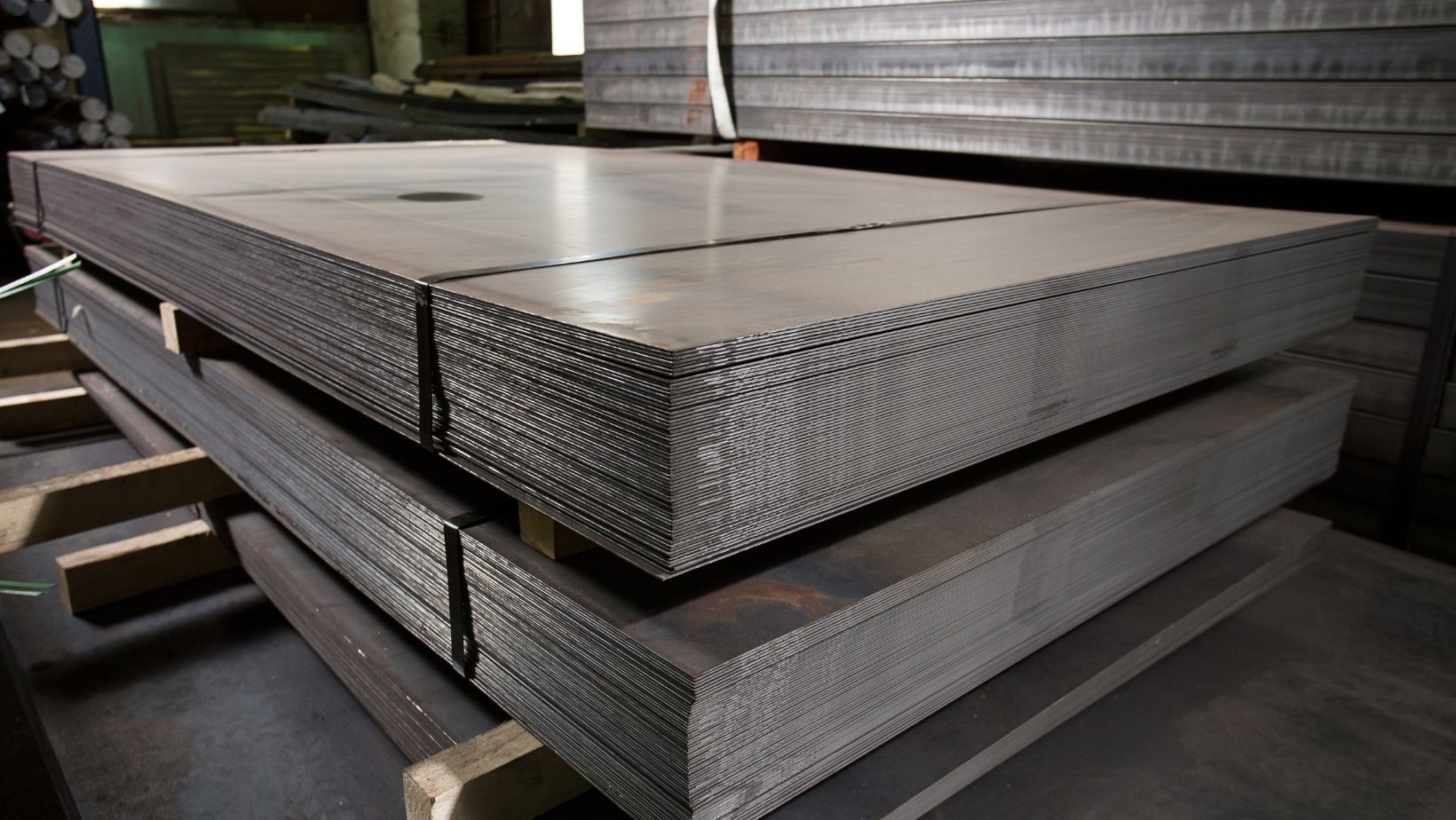

Steel Sheet Metal

Steel sheet metal is strong and durable, making it a popular choice for construction and manufacturing. It comes in different types, such as:

- Carbon Steel: This is a mix of iron and carbon. It is strong and affordable.

- Stainless Steel: It resists rust and corrosion, so it is often used in kitchens and medical equipment.

- Galvanized Steel: This steel is coated with zinc to protect it from rust.

Aluminum Sheet Metal

Aluminum sheet metal is lightweight and corrosion-resistant. It is easy to work with, making it popular in the automotive and aerospace industries. It is also used in household items like roofing and gutters.

Copper Sheet Metal

Copper is a great conductor of electricity and heat. It is often used in electrical wiring and decorative items. Copper sheet metal is also resistant to corrosion.

Brass Sheet Metal

Brass is an alloy made of copper and zinc. It has a gold-like appearance, making it a popular choice for decorative purposes, such as jewelry and home accents.

Common Fabrication Techniques

Various fabrication techniques are used to create products from sheet metal. These techniques involve cutting, bending, and joining sheet metal into the desired shapes. Here are some of the most common methods:

Cutting

Cutting is the first step in sheet metal fabrication. It involves slicing the sheet into the required size or shape. Common cutting methods include:

- Shearing: Using a machine to cut straight lines.

- Laser Cutting: A precise method using a laser beam.

- Plasma Cutting: Cutting with a high-temperature plasma torch.

Bending

After cutting, the sheet is bent to form specific shapes. This is done using tools like press brakes or manual bending machines. Bending is common when creating parts like brackets and enclosures.

Stamping

Stamping involves pressing a tool into the sheet metal to create patterns or shapes. This method is often used to produce automotive parts and metal decorations.

Welding

Welding joins multiple pieces of sheet metal together. It uses heat to melt and fuse the edges, creating a strong bond. Welding is commonly seen in construction and manufacturing industries.

Rolling

Rolling is a process that shapes sheet metal into cylindrical or curved forms. It is used to create pipes and tubes.

Why Sheet Metal Is Important

Sheet metal is essential in many industries because it is versatile and cost-effective. Its thin nature makes it easy to work with, and its wide range of types allows for different applications. For example:

- In construction, sheet metal is used for roofs, ducts, and structural components.

- In automotive, it is used for car bodies and parts.

- In electronics, it is used for casings and housings.

Rapid Axis

One key name in sheet metal fabrication and manufacturing is Rapid Axis. This company specializes in providing high-quality sheet metal parts quickly and efficiently.

What Makes Rapid Axis Stand Out?

Rapid Axis offers several services that make it a popular choice for businesses:

- Fast Turnaround: They understand the importance of meeting deadlines and ensuring that parts are delivered on time.

- Custom Fabrication: They can create custom sheet metal parts according to specific designs and requirements.

- Advanced Techniques: Rapid Axis uses modern equipment and methods, such as CNC machining and laser cutting, to ensure precision and quality.

- Wide Range of Materials: They work with various types of sheet metal, including steel, aluminum, and copper.

If you’re looking for reliable sheet metal fabrication, Rapid Axis is a trusted partner for many industries.

Finishing Techniques for Sheet Metal

After fabrication, finishing techniques are applied to improve the appearance and durability of sheet metal products. Here are some common finishing methods:

Painting and Powder Coating

These methods add a protective layer to prevent rust and corrosion. They also enhance the visual appeal of the product.

Polishing

Polishing makes the surface smooth and shiny. It is often used for decorative items.

Anodizing

Anodizing is a process used for aluminum sheet metal. It creates a protective oxide layer that prevents corrosion and adds color.

Galvanizing

Galvanizing involves coating the sheet metal with zinc to protect it from rust. This is common for outdoor applications like fences and poles.

Challenges in Sheet Metal Fabrication

Despite its many advantages, working with sheet metal comes with challenges:

- Precision Requirements: Small errors can lead to wasted materials or unusable products.

- Material Handling: Thin sheet metal can be fragile and requires careful handling.

- Costs: High-quality equipment and skilled labor are needed for advanced techniques.

The Future of Sheet Metal Fabrication

With advancements in technology, sheet metal fabrication is becoming more efficient and precise. Automated machines and software, such as CAD (Computer-Aided Design), allow for faster and more accurate designs. Companies like Rapid Axis are leading the way by adopting these innovations.

Conclusion

Sheet metal is a vital material in modern industries, offering versatility and strength. Whether it’s steel, aluminum, copper, or brass, each type of sheet metal has its unique properties and uses. Fabrication techniques like cutting, bending, and welding turn these sheets into everyday products we rely on.

If you’re in need of high-quality sheet metal fabrication, consider partnering with Rapid Axis. Their expertise and advanced techniques ensure that you get the best results for your projects.

By understanding the different types of sheet metal and their fabrication methods, you can make informed decisions for your next project.