Well, I’ve been a field man for many years, and I see how much custom parts manufacturing has transformed through on-demand CNC machining. Speed, precision, and, most importantly, flexibility if we speak of on-demand machines are the advantages of traditional manufacturing that they can’t even compete with. Thus, let’s examine why you might want to find this CNC technology to produce your custom pieces.

What is On-Demand CNC Machining?

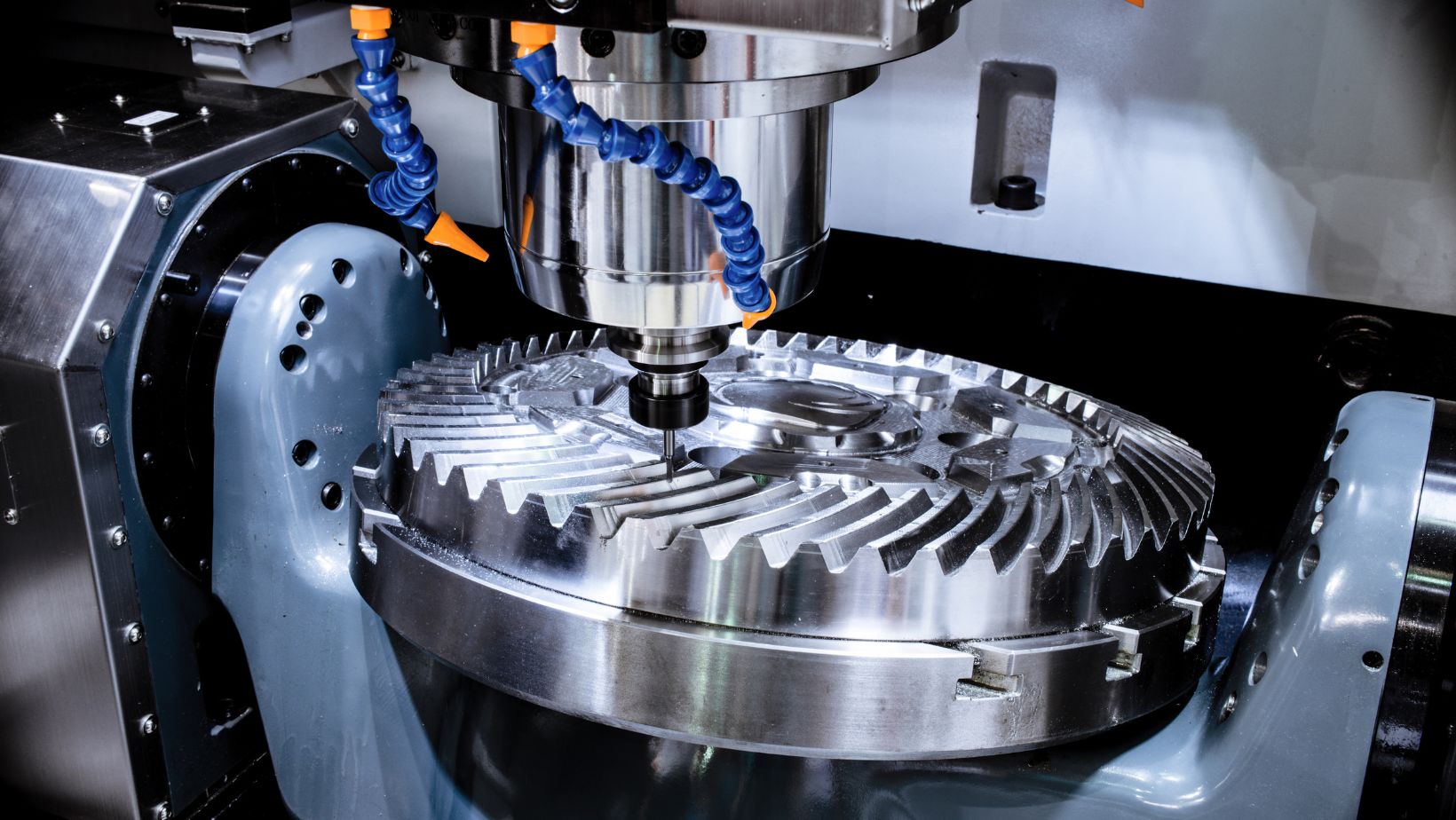

On-demand CNC machining services are an advanced process of manufacturing. It deploys digitally controlled machines to create the needed parts. The distinctive feature of this method is that it allows making custom parts quickly without a big order quantity or long lead time.

Key Benefits of On-Demand CNC Machining

1. Speed and Efficiency

Looking at On-demand CNC machining, I can tell you that the speed is a huge plus. You put in the order, and the machine gets to work. This is their advantage over the traditional way of production.

2. High Precision and Accuracy

Last but not least, CNC machines have great accuracy. They can make parts that differ from the dimensions of the original model by using less than thin hair. This fact means that the complex parts are produced meeting the exact dimensions and reliabilities in the right way.

3. Cost-Effectiveness

On-demand CNC machining is a very economical process. You mean you only buy the parts you really need when you need them. The process reduces waste by avoiding the need for bulk production to produce small lots. But you can use just the number of prototypes you need.

4. Material Versatility

CNC machines have become so efficient in their work that it is unbelievable. The fact that they are able to work with all types of (be it solid or soft) materials with equal accuracy is a big plus. Now, they can manipulate compositions of materials, i.e., metals, plastics, woods, and composites.

Industries Benefiting from On-Demand CNC Machining

Aerospace

Aerospace is the aircraft industry which usually needs precise parts but at the same time, they are very light. On-demand CNC machining results in the production of these parts quickly and accurately. This is vital in an industry, in which security and precision must be at the top.

Automotive

Car manufacturers need parts that are used for the making of new models or the adjusting of the ones already existing with them. On-demand CNC machining indicates the fast production of these parts.

Medical Devices

Most of the time, it happens that medical instruments, which are the most difficult-to-produce parts, are needed for such surgeries. On-demand CNC machining can manufacture these parts with high precision. But majorly it is a mainstay of areas like implants and surgical tools because of its accuracy.

Electronics

Of course, the electronics industry, for instance, requires a small but very precise component. On-demand CNC machining does the job quickly, and accurately. The boot sector requires these types of components, especially in circuit boards and device cases. CNC accuracy is very efficient in reducing computer size.

The On-Demand CNC Machining Process

1. Design Submission

Part of the process calls for you to send your design. Generally, you will need to submit a 3D CAD file. It is the file that contains all the information about your part.

It is important to check with the manufacturer that your part is correctly designed and complete otherwise, it can cause some technical issues.

2. Quote and Review

The manufacturer will verify your design. A contract amount is set up based on the quantity, complexity, and material you select. This is also the time when you negotiate some modifications or additional characteristics.

3. Manufacturing

When the quote is confirmed, the manufacturing will come on. Can you imagine the fact that it is done by the CNC machine that reads your plan and executes it? The method simplifies the work while ensuring compatibility in all the parts.

4. Quality Control

The next step after manufacturing is quality control for each part. Hence, inspecting the parts before they are packaged for shipment ensures they meet your specifications. Therefore, the cases are rectified before the shipping of these parts.

5. Shipping

The products are then packed and delivered to you. Among other benefits, the on-demand services often provide fast delivery times. Consequently, you will get your parts quickly after the production.

Choosing the Right On-Demand CNC Machining Service

Expertise and Experience

You must consider the company’s reputation and experience in your area. Ask them to list their technical skills and the way they have applied it in the past. Their previous track record can be a big determinant of how your pieces will come out.

Equipment and Technology

Be sure of the kinds of manufacturing equipment and the graphics software they use in-house. Well-maintained, modern devices are essential for the fulfillment of this task.

Quality Control Measures

A service should possess rigid rules for quality control in their production line. Ask them about their evaluation activities and quality standards on this occasion.

They should be prepared to provide you with the necessary details for their manufacturing parts.

Communication and Customer Service

Clear communication is fundamental to a successful collaboration. Be certain that support is prompt and that your queries are addressed. They also should be able to track the shipment whenever you need that service.

Pricing and Turnaround Time

Check the fleet and the delivery times of the various services. Do not forget that the cheapest one does not mean the best quality. Additionally, comparing factors like cost, quality, and speed is useful.

Final Words

The advantages of on-demand CNC machining in custom parts are numerous. Its rapidity, accuracy, and adaptability make it an ideal choice in many industries. However, the gains of the process outweigh the losses in most cases. As technology develops further, the times and the efficiency of on-demand CNC machining are likely to improve. Try the method on your subsequent custom part design to get these results first-hand.